Metal Stamping

What is Metal Stamping?

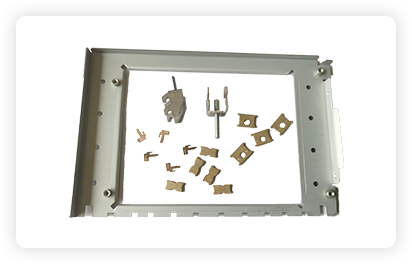

Metal stamping involves converting flat sheet metal into specific shapes. It uses a variety of metal forming techniques including blanking, punching, bending and piercing. It is a fast and cost-effective solution for high-quantity manufacturing. The process involves a stamping die, made custom for the specific part that is being manufactured. Once the initial cost and time to develop the tooling is complete, the versatility of stamping allows a manufacturer to run high volumes of a unique piece in very little time at a lower price. Progressive dies are a popular choice of tooling, and you can learn more about these dies from this video here.

Metal stamping involves converting flat sheet metal into specific shapes. It uses a variety of metal forming techniques including blanking, punching, bending and piercing. It is a fast and cost-effective solution for high-quantity manufacturing. The process involves a stamping die, made custom for the specific part that is being manufactured. Once the initial cost and time to develop the tooling is complete, the versatility of stamping allows a manufacturer to run high volumes of a unique piece in very little time at a lower price. Progressive dies are a popular choice of tooling, and you can learn more about these dies from this video here.

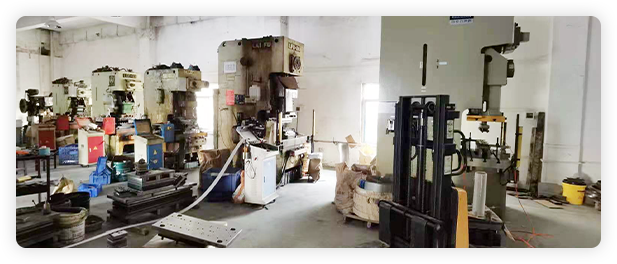

We provides metal stamping services to a variety of industries. We run stampings up to .250” thick, but our specialty is high-volume, tight tolerance, precision stampings in a variety of materials from .003”-.060” thick. Our presses have full feed lines and are die sensor protection ready. We run nearly 60 million stampings per year at a 98% on time delivery rate.

CNC Machining Services - Medium to High-Volume Production

What is CNC Machining?

CNC (Computer Numerical Control) Machining is when pre-programmed computer software controls the movement of tools in machinery. There are many tools available for CNC machines, allowing for a wide range of processes, features and finishes for any given project. These tools remove layers of a material from a stock piece and produces a uniquely designed part. This includes processes like drilling, milling, turning, grinding and more. The CNC process is effective for a wide range of materials and can be automated, allowing for high precision and accuracy. CNC Machining is considered a subtractive manufacturing process, since material is removed from the stock piece. CNC is a great option for many manufacturers looking for consistency and quality.

CNC (Computer Numerical Control) Machining is when pre-programmed computer software controls the movement of tools in machinery. There are many tools available for CNC machines, allowing for a wide range of processes, features and finishes for any given project. These tools remove layers of a material from a stock piece and produces a uniquely designed part. This includes processes like drilling, milling, turning, grinding and more. The CNC process is effective for a wide range of materials and can be automated, allowing for high precision and accuracy. CNC Machining is considered a subtractive manufacturing process, since material is removed from the stock piece. CNC is a great option for many manufacturers looking for consistency and quality.

CNC machining services feature personalized customer service for made-to-order parts and components.

We offer turning, milling, drilling, tapping, boring, and grinding for a variety of materials. We have sub-spindle and live tooling turning capabilities with bar feeding capacity to 3” diameter, a swing of 25.60”, and can turn parts up to 40” long x 14.30” in diameter. Our high-speed vertical and horizontal machining centers produce accurate and efficient machined parts for many industries. Part sizes can reach up to 64” x 34” x 30” for vertical milling and 24”x 24” x 28” for horizontal milling. Our state-of-the-art machinery handles 3- and 4-axis machining while attaining production tolerances to ± .0002”. Other services include pre-production prototypes, engineering and design capabilities and in-house tool, gage and fixture building.

All rights reserved ©Starda Mould(H.K.)Co.,Limited